1 February 2019

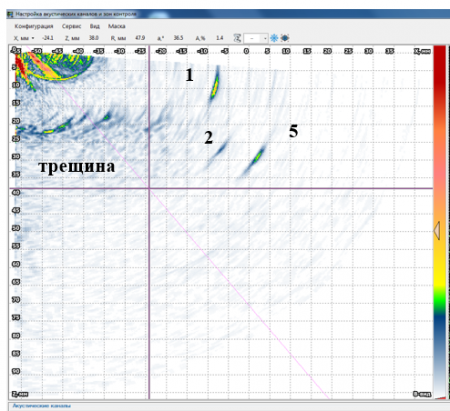

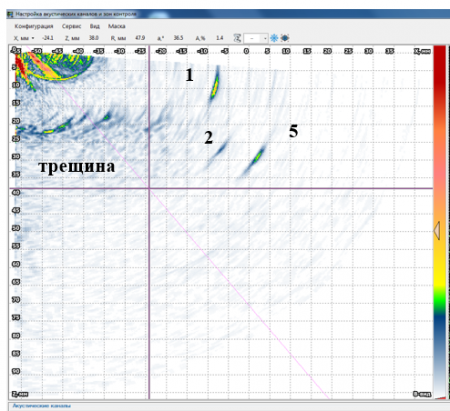

The figure below shows the result of the control from the opposite side. It can be seen that part of the holes and the bottom are shaded by a crack.

Control results in the CFA mode

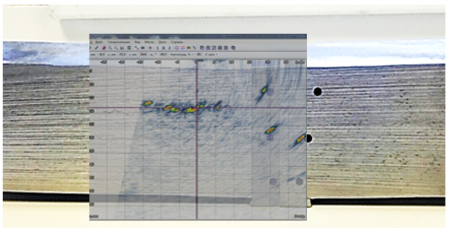

The result of inspection from the crack side with the superimposition of the image of defects on the photo of the sample is shown.

The crack geometry is well revealed and the shading of part of the holes is visible. Due to the continuous focusing, the image quality is higher than when using the FR mode.

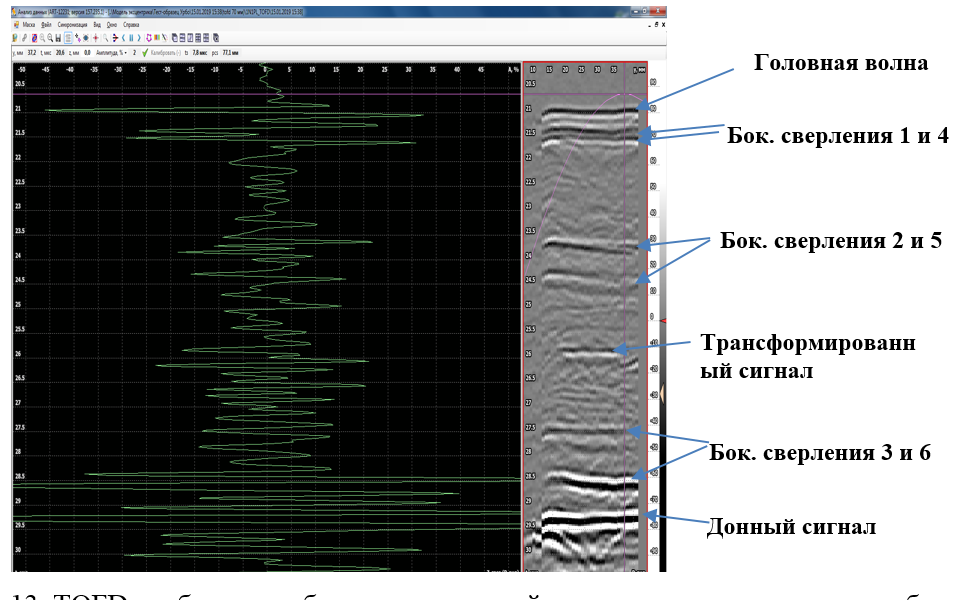

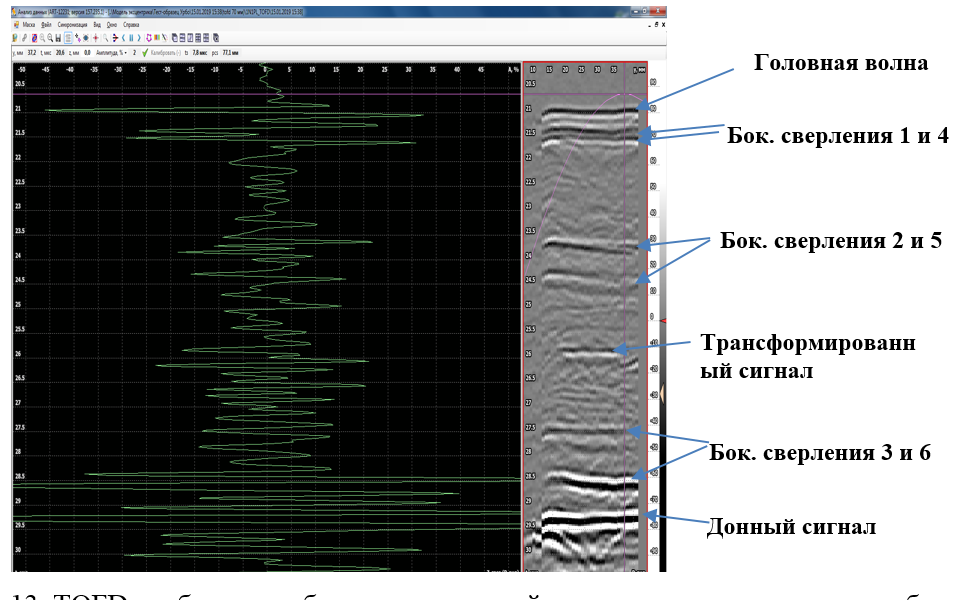

Inspection results in TOFD mode

Various control schemes were selected when using frequencies from 2.5 to 10 MHz for different input angles.

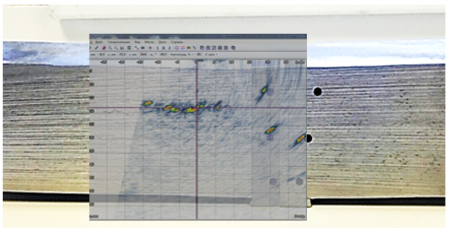

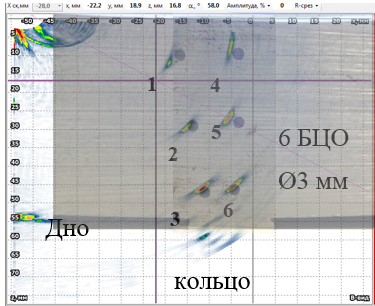

The figure below shows a typical example of a TOFD image obtained by scanning a sample with a SPIDER scanner.

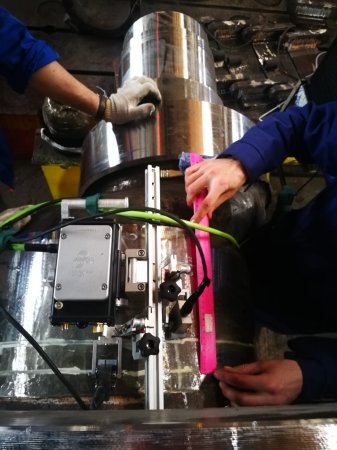

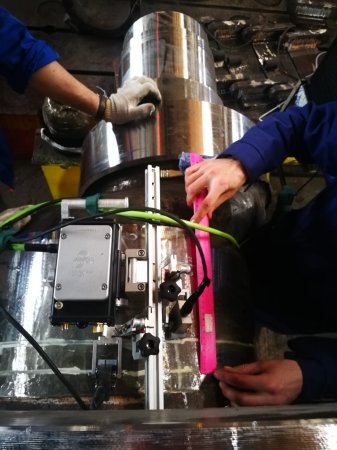

The scanner installed on the object

Conclusions

Ultrasonic inspection of the welded joint of the eccentric

Object of inspection

The laboratory for the use of equipment of the SPC ECHOPLUS conducted a demonstration inspection of a sample of the welded joint of the eccentric pump of the drilling rig.

The parts of the eccentric are made of cast steel and may contain internal defects. The equipment itself is subject to extremely intense loads and requires high sensitivity when detecting defects in the base and pressed metal.

Inspection technology

The test control of the sample was carried out using the AUGUR ART flaw detector, which supports the HEADLIGHT and CFA technology, as well as the AUGUR-T flaw detector, which supports the TOFD technology.

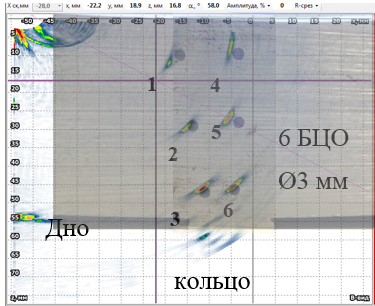

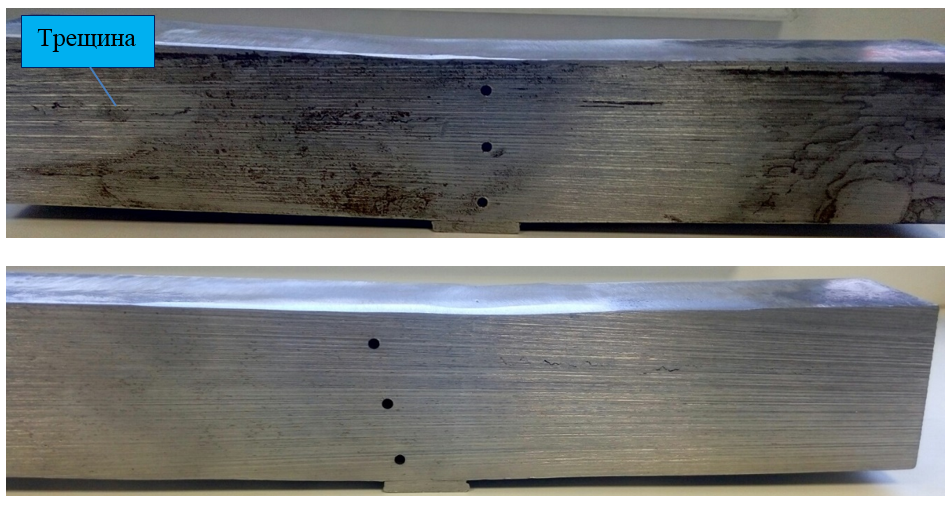

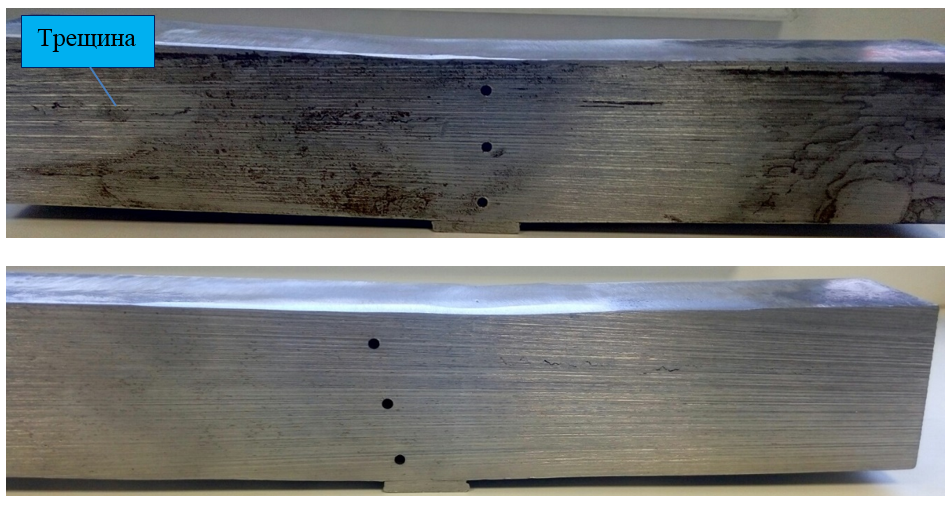

The tuning sample is a flat block with a 50 mm thick weld with a V-shaped cutting with artificial reflectors introduced into it in the form of lateral cylindrical drills with a diameter of 3 mm.

The sample was made from a blank with a horizontal crack, which is visible in the cast metal and was formed during experimentation with heat treatment after welding.

The seam is welded on the lining ring.

The results of the inspection

The results of detecting reflectors in the FR mode operating on a longitudinal wave are shown below. The bottom surface is also visualized.in the headlight mode.

The laboratory for the use of equipment of the SPC ECHOPLUS conducted a demonstration inspection of a sample of the welded joint of the eccentric pump of the drilling rig.

The parts of the eccentric are made of cast steel and may contain internal defects. The equipment itself is subject to extremely intense loads and requires high sensitivity when detecting defects in the base and pressed metal.

Inspection technology

The test control of the sample was carried out using the AUGUR ART flaw detector, which supports the HEADLIGHT and CFA technology, as well as the AUGUR-T flaw detector, which supports the TOFD technology.

The tuning sample is a flat block with a 50 mm thick weld with a V-shaped cutting with artificial reflectors introduced into it in the form of lateral cylindrical drills with a diameter of 3 mm.

The sample was made from a blank with a horizontal crack, which is visible in the cast metal and was formed during experimentation with heat treatment after welding.

The seam is welded on the lining ring.

The results of the inspection

The results of detecting reflectors in the FR mode operating on a longitudinal wave are shown below. The bottom surface is also visualized.in the headlight mode.

The figure below shows the result of the control from the opposite side. It can be seen that part of the holes and the bottom are shaded by a crack.

Control results in the CFA mode

The result of inspection from the crack side with the superimposition of the image of defects on the photo of the sample is shown.

The crack geometry is well revealed and the shading of part of the holes is visible. Due to the continuous focusing, the image quality is higher than when using the FR mode.

Inspection results in TOFD mode

Various control schemes were selected when using frequencies from 2.5 to 10 MHz for different input angles.

The figure below shows a typical example of a TOFD image obtained by scanning a sample with a SPIDER scanner.

The scanner installed on the object

Conclusions

- AUGUR ART and AUGUR E automated ultrasonic inspection systems can be used to control the welded joints of the eccentric using the proposed methods.

- The FAR and CFA methods used in the AUGUR ART system make it possible to identify defects in this type of seams and the near-seam zone even with one-way access using two or three scans with different distances to the center of the seam.

- The CFA method made it possible to clearly identify a horizontal planar defect in the base metal c and obtain an image with a higher resolution.

- The TOFD method used in the AUGUR T system made it possible to identify all reflectors, but due to the presence of a screening reflector (horizontal crack) in the sample, "false" signals are present in the image