24 February 2023

Non-destructive testing of rotary kiln bandages

In January, at one of the cement plants, ECHOPLUS specialists conducted ultrasonic inspection of rotating furnace bandages to identify and visualize internal and surface defects. The control was carried out in the operating mode of the equipment.

The equipment manufactured by ECHOPLUS was used in the control - an AUGUR-ART ultrasonic flaw detector and a scanner with a path sensor, frame and clamps.

Control results

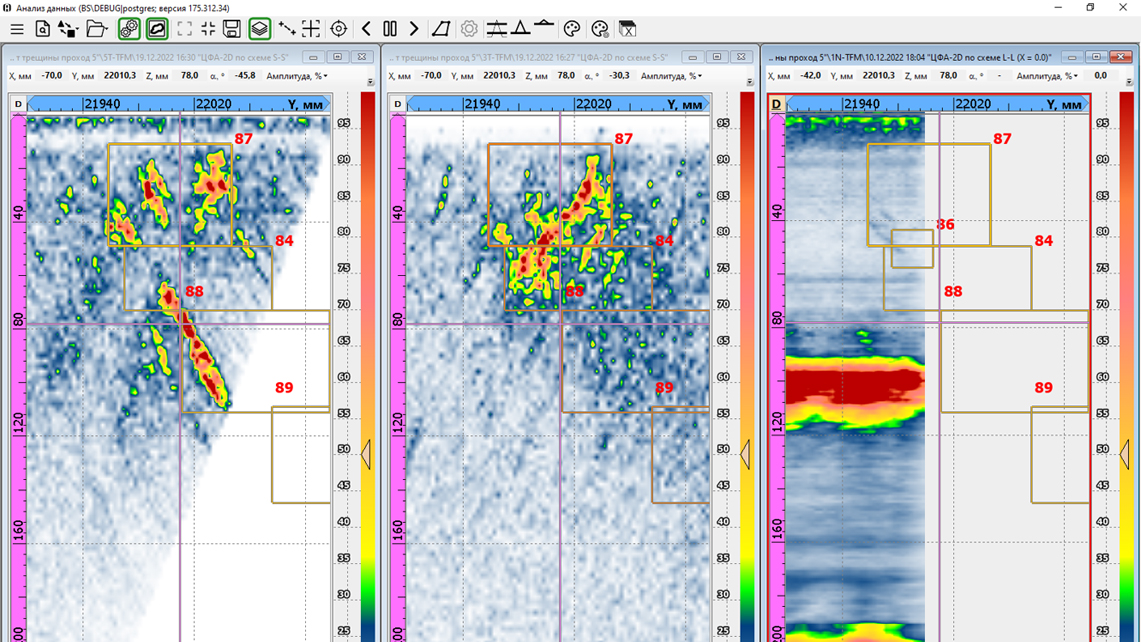

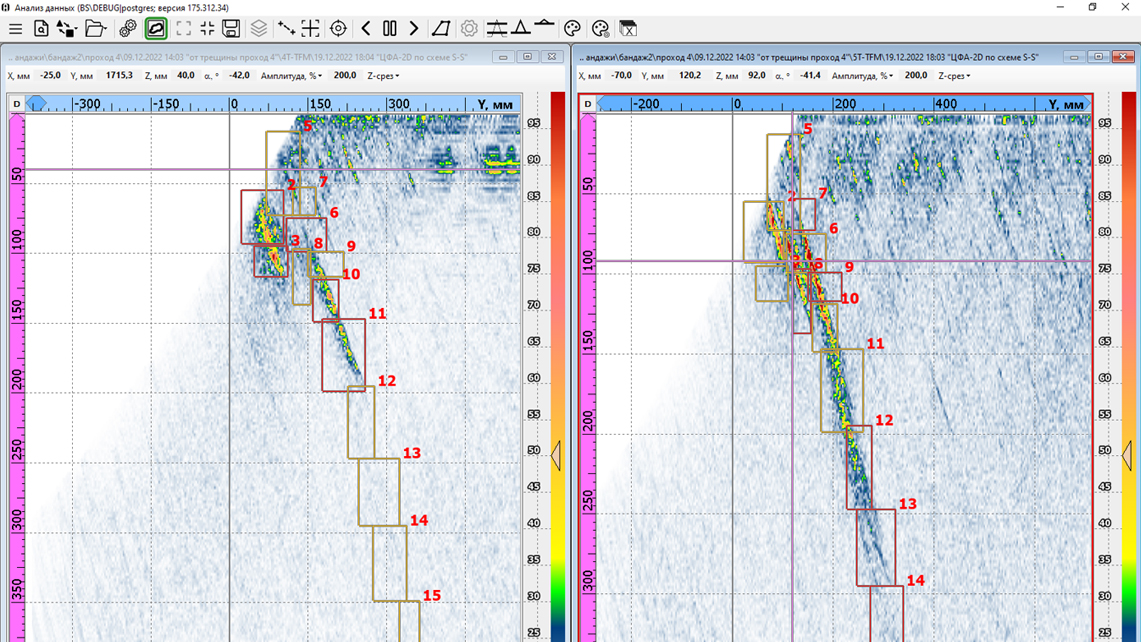

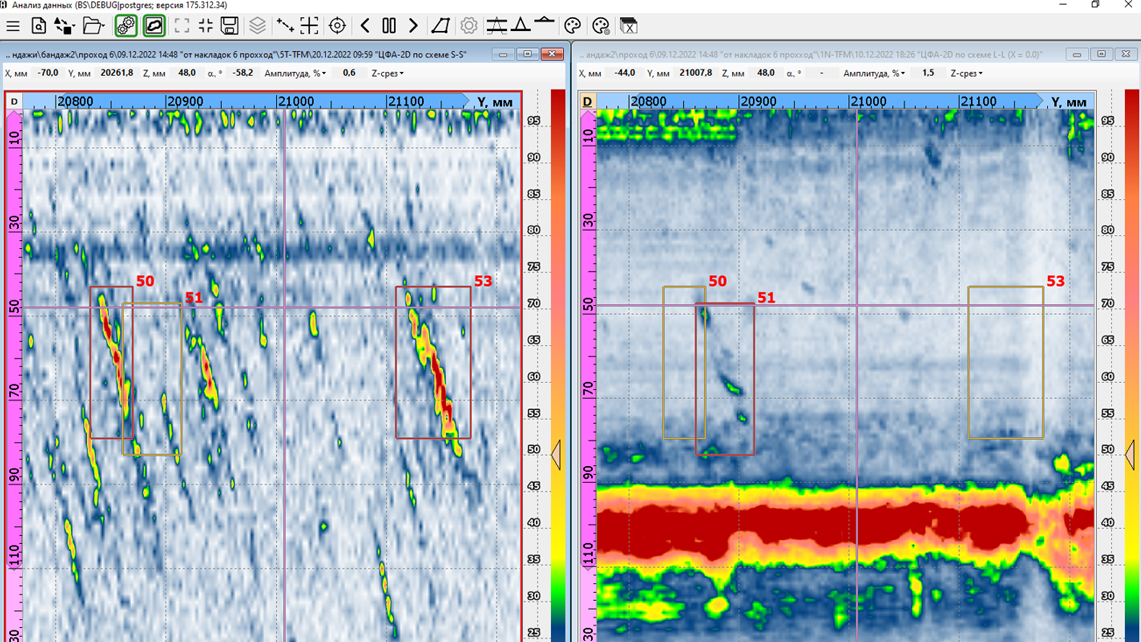

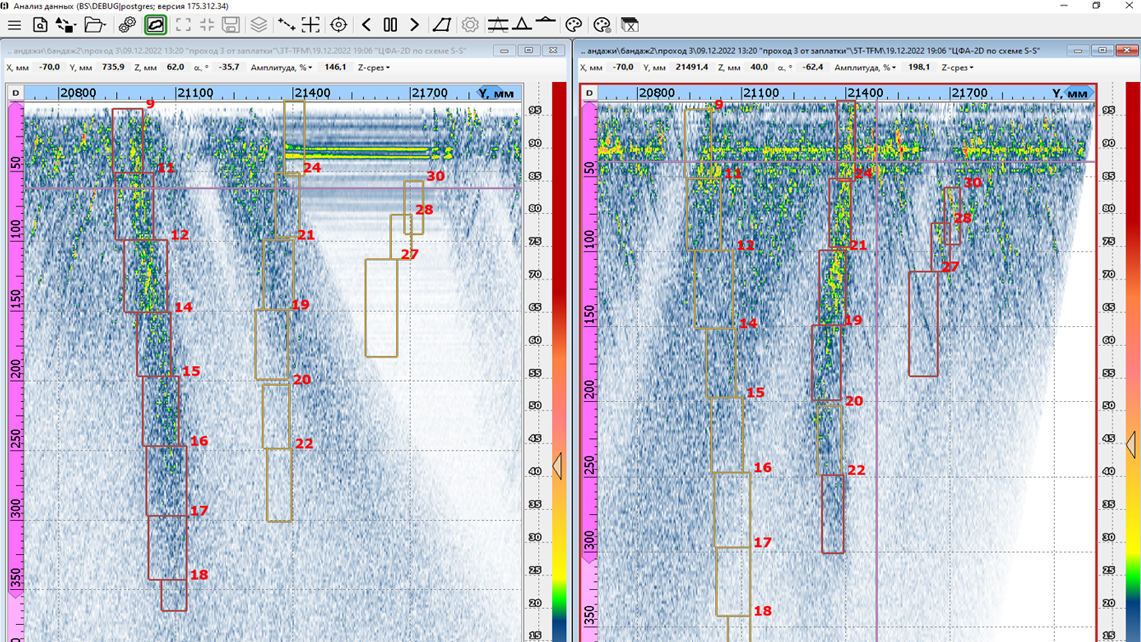

Technological schemes formed as a result of the passages, with descriptions.Defect No. 6. The passage is 540 mm from the hydraulic seal (the end of the passage). Channel 5 is on the left, channel 3 is in the center, and channel 1 is on the right.